Heart Rate Systems

Please contact Telonics if interested in heart rate transmitters.

Telonics implants are constructed with a dual water barrier designed to be fully implantable. Care needs to be taken not to damage the outer wax coating during disinfecting/sterilization (avoid heat) and impantation.

In mammals, the main heart-rate unit is typically placed in the abdominal cavity - one electrode is placed near the sternum while the other is physically separated and often placed on the last floating rib. The exact positioning of the electrodes must be determined by the researcher and optimized for individual species. Seeking a position for electrode implantation which maximizes the QRS complex of the cardiac depolarization is important, as is minimizing the P and T waves of the EKG waveform. The QRS depolarization event triggers a single transmission of the heart rate unit. The units have an automatic gain control (AGC) to help ensure that the threshold voltage can be established and maintained. The AGC helps compensate for changes in body position and buildup of collagen in the tissue near the electrode implantation site over time. Telonics heart rate units also feature a failsafe pulse rate which is implemented if the HR detection circuitry cannot detect the depolarization of the heart muscle.

Although implants often have less range compared to externally mounted units, Telonics "tunes" the implant's antenna to match to the dialectic of the body maximizing range performance of the system.

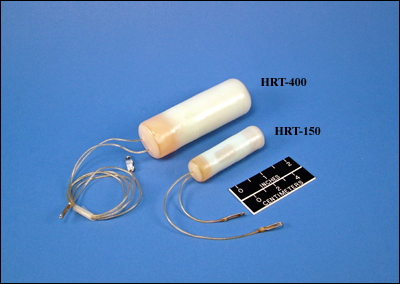

Models

| Model | Dimensions L x Dia (in, cm) |

Weight (g) | Battery Life @60BPM Std Power |

|---|---|---|---|

| HR-150 | 2.7 x 0.9 6.9 x 2.3 |

35 | 4.1 |

| HR-200 | 3.0 x 0.9 7.6 x 2.3 |

40 | 7.5 |

| HR-200 | 3.0 x 0.9 7.6 x 2.3 |

40 | 7.5 |

| HR-200 | 3.0 x 0.9 7.6 x 2.3 |

40 | 7.5 |

* Note: For Heart Rate transmitters, operational life is dependent on the heart rate of the animal.